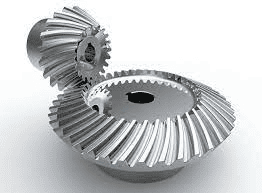

Helical gears are designed in such a way that they have the ability to spin, hence facilitating the movement of the shaft of the machine. Bevel gears are also similar to the helical gears in the sense that both of these gear types can also rotate. However, the bevel gears do not allow the teeth to move in opposite directions, unlike the helical gears that have the ability to move in clockwise and anti-clockwise directions. In other words, the teeth of these gears can rotate in any direction as well as they have the ability to move in any direction.

One of the most important things that an engine can have is an effective and efficient transmission, which allows the transmission of the power into the axle of the machine that is then transferred to the different gear types. The transmission of the power or the energy into the axle allows it to work efficiently and this in turn allows the engine to function properly. The best possible means of achieving an efficient engine is by having good and high efficiencies in the transmission of the power or the energy into the axle. For Fluid Power products, contact Dana Sac

A spur gear features parallel shafts with teeth that sit parallel to the shaft axis. There is only one single line of contact through the teeth and this makes spur gears louder than helical gears, for example. A worm gear is used in applications that need a right angle or shafts which don’t intersect.